|

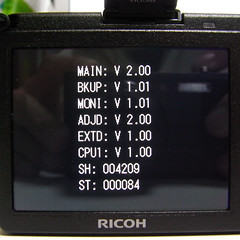

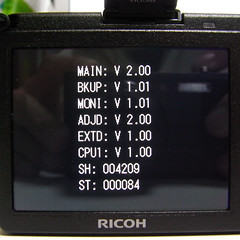

| Ricoh GR Digital II FirmwareUpdate V2.0 (Photo credit: takuhitosotome) |

Kode Error Mesin Fotocopy Ricoh [

Error Codes Ricoh Copier] atau Technical

SC CODE Ricoh adalah suatuh keadaan dimana

Mesin Photocopy Ricoh memberitahukan letak kesalahan atau system error pada mesin fotocopy khususnya merek

RICOH analog.

Dibawah ini saya berikan

Kode Service [

kode Error]

Mesin RICOH Analog FT 7650

1.1 EXPOSURE

SC 101 - Exposure lamp malfunction - abnormal On/Off

Definition: [level: A]

During the lamp off condition, the optics control board detects a lamp voltage.

Possible causes

• Exposure lamp open

• Triac shorted

• Exposure lamp thermoswitch open

• Optics control board defective

SC 103 - Power source frequency detection error

Definition: [level: D]

Detects frequencies out of the 45Hz to 65Hz range.

Possible causes:

• Abnormal power source

• Electrical noise

• AC drive board defective

• Optics control board defective

SC 104 - Exposure lamp malfunction - abnormal off

Definition: [level: D]

The scanner start signal is received even if the main relay off condition is detected.

Possible causes:

• Main relay defective

• Communication error between the main control board and the optics control board because of a poor harness connection.

• Optics control board defective

Troubleshooting

1.2 SCANNER

SC 120 - Scanner home position sensor abnormal - stays off

Definition: [level: D]

The scanner home position sensor does not detect the on condition even if the scanner returns home.

Possible causes:

• Scanner home position sensor defective

• Optics control board defective

SC 121 - Scanner home position sensor abnormal - stays on

Definition: [level: D]

The scanner home position sensor does not detect the off condition even if the scanner leaves the scanner home position sensor by 120 mm.

Possible causes:

• Scanner home position sensor defective

• Scanner motor defective

• Scanner HP sensor short

SC 125 - Low scanner speed

Definition: [level: D]

The scanner speed, detected by the optics control board through the encoder, is lower than the specified speed.

Possible causes:

• Scanner drive motor defective

• Optics Control Board defective

SC 126 - High scanner speed

Definition: [level: D]

The scanner speed, detected by the optics control board through the encoder, is higher than the specified speed.

Possible causes:

• Scanner drive motor defective

• Optics control board defective

SC 127 - Scanner drive motor encoder failure

Definition: [level: D]

Scanner rotating direction detected by the optics control board through the encoder is opposite to the specified direction.

Possible causes:

• Scanner drive motor defective

• Optics control board defective

1.3 LENS MAGNIFICATION

SC 140 - Lens vertical home position sensor abnormal - stays off

Definition: [level: D]

When the lens returns to the home position, the lens vertical home position sensor does not detect the on condition for 2 seconds or more, and more than twice.

Possible causes:

• Lens vertical home position sensor shorted

• Lens vertical drive motor defective

• Optics control board defective

SC 141 - Lens vertical home position sensor abnormal - stays on

Definition: [level: D]

When the lens returns to the home position, the lens vertical home position sensor does not detect the off condition for 3.5 seconds or more, and more than twice.

Possible causes:

• Lens vertical home position sensor open

• Lens vertical drive motor defective

• Optics control board defective

SC 142 - Lens horizontal home position sensor abnormal - stays off

Definition: [level: D]

When the lens returns to the home position, the lens horizontal home potion sensor does not detect the on condition for 1.7 seconds or more, and more than twice.

Possible causes:

• Lens horizontal home position sensor short

• Lens horizontal drive motor defective

• Optics control board defective

SC 143 - Lens horizontal home position sensor abnormal - stays on

Definition: [level : D]

When the lens leaves from the home position, the lens horizontal home potion sensor does not detect the off condition for 2.3 seconds or more, and more than twice.

Possible causes:

• Lens horizontal home position sensor open

• Lens horizontal drive motor defective

• Optics control board defective

Troubleshooting

SC 144 - 3rd scanner home position sensor abnormal - stays off

Definition: [level: D]

When the 3rd scanner returns to the home position, the 3rd scanner home position sensor does not detect the on condition for 1.2 seconds or more, and more than twice.

Possible causes:

• 3rd scanner home position sensor shorted

• 3rd scanner drive motor defective

• Optics control board defective

SC 145 - 3rd scanner home position sensor abnormal - stays on

Definition: [level: D]

When the 3rd scanner leaves from the home position the 3rd scanner home position sensor does not detect the off condition for 2.0 seconds or more, and more than twice.

Possible causes:

• 3rd scanner home position sensor open

• 3rd scanner drive motor defective

• Optics control board defective

SC 146 - Abnormal magnification operation

Definition: [level: D]

The lens vertical drive motor or the lens horizontal drive motor move for no apparent reason in the ready condition.

Possible causes:

• Lens vertical drive motor defective

• Lens horizontal drive motor defective

• 3rd scanner drive motor defective

• Optics control board defective

1.4 OPTICS

THERMISTOR

SC 190 - Optics thermistor open

Definition: [level: D]

The optics thermistor is open.

Possible causes:

• Optics thermistor open

NOTE: When the optics thermistor is shorted, no SC code is indicated. The exhaust fan rotates quickly and continuously.

SC 191 - Scanner motor thermistor open

Definition: [level: D]

The scanner motor thermistor is open.

Possible causes:

• Scanner drive motor defective

SC 192 - High Scanner Motor Temperature (70 CPM)

Definition: [level: D]

The temperature of the scanner motor is 80°C or more.

Possible causes:

• Scanner motor clooing fan defective

1.5 MAIN CHARGE

SC 302 - Charge corona leakage

Definition: [level: D]

The charge power pack detects a charge corona leakage (output: 0 V) for 4.8 ms, or detects the output to be more than 7 kV, 10 times in one job.

Possible causes:

• Main charge corona unit defective

• Main charge power pack defective

• High voltage control board defective

SC 303 - Charge corona wire cleaner failure

Definition: [level: C]

The current of the charge corona wire cleaner drive motor is over the specified current within 4 seconds after the cleaner motor starts. The charge corona wire cleaner does not move back to the end block within 30 seconds.

Possible causes:

• Charge corona wire cleaner drive motor defective

• Insufficient lubrication for the charge corona wire cleaner drive mechanism (G501 grease)

• High voltage control board defective

1.6 DEVELOPMENT

SC 341 - Development motor locked

Definition: [level: D]

Development motor lock signal stays low more than 1 second in development motor on condition.

Possible causes:

• Extra load in the development unit

• Development motor defective

• Main control board defective

SC 342 - Toner collection motor locked

Definition: [level: D]

The toner collection sensor output does not change (OFF/ON or ON/OFF) for more than 2.55 seconds in the toner collection motor on condition.

Possible causes:

• Toner collection sensor defective

• Toner collection motor defective

• Toner clog in the toner collection pipe

SC 343 - Toner collection bottle at improper position

Definition: [level: D]

Toner bottle set switch is off and the front door is closed.

Possible causes:

• Toner collection bottle set switch defective

• Toner collection bottle is set incorrectly

1.7 PROCESS SENSOR

SC 351 - Abnormal Vsg Detection (Vsg > 4.2V)

Definition: [level: C]

The detected Vsg value is over 4.2 V.

Possible causes:

• ID sensor defective

• Main control board defective

SC 352 - Incomplete TD sensor initial setting

Definition: [level: C]

The output voltage of the TD sensor is higher than 2.6 V or lower than 2.4 V during the developer initial setting mode. VOUT to get 2.5 V for the TD sensor output is higher than 10 V or lower than 2 V.

Possible causes:

• Connector [A] not set correctly

• Toner density sensor defective

• Abnormal toner concentration

SC 353 - Abnormal Vsp Detection (Vsp ³ 2.5 V: lighter pattern)

Definition: [level: C]

Vsp is 2.5 V or higher.

Possible causes:

• ID sensor defective

• OPC drum

• High voltage control board defective

• Poor contact of the development bias terminal [A] A176T502.wmf

SC 354 - Abnormal Vsg detection (Vsg £ 2.5 V)

Definition: [level: C]

Vsg is 2.5 V or less.

Possible causes:

• ID sensor defective

• OPC drum

• Dirty charge corona casing

• Quenching lamp defective

• Erase lamp defective

• Cleaning blade defective

• Dirty ID sensor

SC355 - Abnormal VTD detection (VTD ³ 4 V)

Definition: [level: C]

VTD is 4 V or higher.

Possible causes:

• Toner density sensor defective

• Toner concentration too low

SC 356 - Abnormal VTD detection (VTD < 0.5 V)

Definition: [level: C]

VTD is less than 0.5 V.

Possible causes:

• Toner density sensor defective

• Toner concentration is too high

SC 357 - Abnormal Vsp detection (Vsp/Vsg ³ 25%)

Definition: [level: C]

Vsp/Vsg is 25% or higher.

Possible causes:

• ID sensor defective

• OPC drum

• Dirty ID sensor

SC 358 - Abnormal Vsp detection (Vsp/Vsg < 2.5%)

Definition: [level: C]

Vsp/Vsg is less than 2.5%.

Possible causes:

• ID sensor defective

• OPC drum

• Toner scattering

SC 361 - Incomplete drum potential sensor calibration

Definition: [level: C]

When the process control initial setting is performed and a development bias of –100 V or –800 V is applied to the drum shaft, the drum potential voltage is out of these ranges: 0.1 £ V–100 £ 0.7 [V] or 2.7 £ V–800 £ 4.2 [V].

Possible causes:

• Drum potential sensor defective

• Drum shaft terminal not grounded

• OPC drum

• Main charge corona unit defective

SC 364 - Abnormal VD detection

Definition: [level: C]

VD is out of specification (VR + 770 ± 20 V).

Possible causes:

• Drum potential sensor defective

• OPC drum

• Main charge corona unit defective

SC 365 - Abnormal VL detection

Definition: [level: C]

VL is out of specification (VR + 140 ± 20 V).

Possible causes:

• Drum potential sensor defective

• OPC drum

• Main charge corona unit defective

• Optics too dirty

SC 366

Definition: [level: C]

VR is larger than 360 V in the process control initialization.

Possible causes

• OPC drum

• Drum shaft terminal not ground

1.8 TRANSFER CURRENT

SC 402 - Transfer current leakage

Definition: [level: D]

When the transfer power pack output voltage exceeds 4.5 kV for 200 ms or more, the output current is multiplied by 0.8. If this condition occurs 11 time in a row, an SC is displayed.

Possible causes:

• Transfer belt defective

• Transfer power pack defective

• Poor contact at transfer bias roller, discharge plate terminals

1.9 DRUM

SC 440 - Abnormal main motor speed

Definition: [level: D]

Lock signal stays low in the main motor on condition for 1.0 second or more.

Possible causes:

• Main motor defective

SC 442 - Drum thermistor open

Definition: [level: D]

The drum thermistor is open.

Possible causes:

• Drum thermistor defective

1.10 PAPER FEED

SC 500 - Abnormal manual feed drive motor speed

Definition: [level : D]

Lock signal stays low in the manual feed motor on condition for 1.0 second or more.

Possible causes:

• Manual feed motor defective

SC 501 - Abnormal paper feed drive motor speed

Definition: [level: D]

Lock signal stays low in the paper feed motor on condition for 1.0 second or more.

Possible causes:

• Paper feed motor defective

• Paper feed control board defective

SC 502 - Abnormal 1st lift motor movement

Definition: [level: B]

The 1st lift sensor detects high condition for 10 seconds or more after the 1st lift motor starts. The first time, after the paper tray is opened and closed, the 1st lift motor starts again. If the above condition occurs twice, this SC is displayed.

Possible causes:

• 1st lift sensor shorted

• 1st lift motor defective

• Paper feed control board defective

SC 503 - Abnormal 2nd lift motor movement

Definition: [level: B]

The 2nd lift sensor detects the high condition for 10 seconds or more after the 2nd lift motor starts. The first time, after the paper tray is opened and closed, the 2nd lift motor starts again. If the above condition occurs twice, this SC is displayed.

Possible causes:

• 2nd lift sensor shorted

• 2nd lift motor defective

• Paper feed control board defective

SC 504 - Abnormal 3rd lift motor (1.5 k LCT motor for A096 copier) movement

Definition: [level: B]

The 3rd lift sensor detects the high condition for 10 seconds or more after the 3rd lift motor starts. The first time, after the paper tray is opened and closed, the 3rd lift motor starts again. If the above condition occurs twice, this SC is displayed.

Possible causes:

• 3rd lift sensor shorted

• 3rd lift motor (1.5 k LCT motor for A096 copier) defective

• Paper feed control board defective

SC 506 - Abnormal 3.5 k LCT motor movement

Definition: [level: B]

The LCT lift sensor detects the low condition for 10 seconds or more after the LCT motor starts. The first time, after the LCT cover is opened and closed, the LCT motor starts again. If the above condition occurs twice, this SC is displayed.

Possible causes:

• LCT motor defective

• LCT lift sensor shorted

SC 507 - Abnormal 3.5 k LCT feed motor movement

Definition: [level: B]

The LCT feed motor is locked for 1 second or more after this motor starts.

Possible causes:

• LCT feed motor defective

SC 508 - Abnormal tandem rear fence drive motor movement

Definition: [level: B]

It takes 10 seconds or more for the rear fence return sensor to detect the on condition after the rear fence drive motor starts. It takes 10 seconds or more for the rear fence home position sensor to detect the on condition after this fence starts moving to the home position. When the tray is set, the rear fence return sensor and the rear fence the home position sensor are on.

Possible causes:

• Rear fence drive motor defective

• Rear fence HP sensor defective

• Rear fence return sensor defective

SC5 10 - Abnormal tandem side fence home position detection - stays off

Definition: [level: B]

When the side fence goes back to the home position or the side fence drive motor works to open the fence, the side fence positioning sensor does not detect the on condition for 5 seconds or more.

Possible causes:

• Side fence drive motor defective

• Side fence positioning sensor open

SC 511 - Abnormal tandem side fence home position detection - stays on

Definition: [level: B]

When the side fence goes back to the home position or the side fence drive motor works to close the fence, the side fence positioning sensor stays on for 5 seconds.

Possible causes:

• Side fence drive motor defective

• Side fence positioning sensor shorted

1.11 DUPLEX

SC 520 - Abnormal fusing/duplex drive motor movement

Definition: [level: D]

The lock signal stays low for 1.0 second after the fusing/duplex drive motor starts.

Possible causes:

• Fusing/duplex drive motor defective

• Cleaning roller is too dirty and applies a great load to the fusing/duplex drive motor.

SC 522 - Abnormal jogger home position sensor detection - stays off

Definition: [level: B]

The jogger home position sensor does not detect the on condition for 5 seconds or more after the fusing/duplex drive motor starts.

Possible causes:

• Jogger motor defective

• Jogger HP sensor open

SC 523 - Abnormal jogger home position sensor detection - stays on

Definition: [level: B]

The jogger home position sensor does not detect the off condition for 1 second after its sensor detects the on condition in the initializing mode.

Possible causes:

• Jogger drive motor defective

• Jogger HP sensor shorted

1.12 FUSING

SC 541 - Fusing thermistor open

Definition: [level: A]

Detects the fusing thermistor open condition for 2 ms or more after turning the main switch on.

Possible causes:

• Fusing thermistor open

• Optics control board defective

SC 542 - Start key stays red

Definition: [level: A]

The fusing temperature does not reach the specified temperature after 5 minutes from turning the main switch on.

Possible causes:

• Fusing lamp defective

• AC Drive board defective

• Fusing thermistor defective

SC 543 - Fusing overheat (detected by the main control board)

SC 544 - Fusing overheat (detected by the optics control board)

Definition: [level: A]

The fusing temperature stays over 231°C for 5 seconds.

Possible causes:

• AC drive board defective

• Fusing thermistor defective

• Optics control board defective

• Main control board defective

SC 545 - Low fusing temperature (detected by the main control board)

SC 546 - Low fusing temperature (detected by the optics control board)

Definition: [level: A]

The fusing temperature stays lower than 100°C for 5 seconds after the machine becomes ready.

Possible causes:

• Fusing thermistor defective

• AC drive board defective

• Fusing lamp open

• Main control board defective

• Optics control board defective

SC 547 - Fusing lamp continuously lit

Definition: [level: A]

Fusing lamp continuously lights for 70 seconds after the machine becomes ready. However, if the door is open, paper jams, or the fusing unit is out of position, the ready condition is canceled and the main relay opens.

Possible causes:

• AC drive board

SC 548 - Unstable fusing temperature

Definition: [level: A]

If the fusing temperature changes by 21°C/second four times in 1 minute, this SC is displayed.

Possible causes:

• AC drive board defective

• Thermistor defective

1.13 SYSTEM CONTROL

SC 600 - Communication error (main control board and operation panel)

Definition: [level: D]

The main control board does not communicate with the operation panel.

Possible causes:

• Main control board defective

• Operation panel defective

• Harness defective

SC 601 - Communication error (main control board and optics control board)

Definition: [level: D]

The main control board does not communicate with the optics control board.

Possible causes:

• Main control board defective

• Optics control board defective

• Harness defective

SC 603 - Main control board malfunction (CPU)

Definition: [level: D]

Communication to the main control board is not completed.

Possible causes:

• Main control board defective

SC 620 - Communication error (main control board and DJF/RDH main board)

Definition: [level: B]

The main board does not communicate with the DJF/RDH main board.

Possible causes:

• Main control board defective

• DJF/RDH main board defective

• Harness defective

• Fiber optics defective

SC 621 - Communication error (main control board and sorter staplers/finisher main board)

Definition: [level: D]

The main control board does not communicate with the sorter stapler/finisher main board.

Possible causes:

• Main control board defective

• Sorter stapler/finisher main board defective

• Harness defective

• Fiber optics defective

1.14 DUAL JOB FEEDER/RECIRCULATING DOCUMENT HANDLER

SC 700 - Abnormal DJF/RDH feed-in motor movement

SC 701 - Abnormal DJF/RDH transport belt motor movement

SC 702 - Abnormal DJF/RDH feed out motor movement

SC 703 - Abnormal RDH inverter motor movement

Definition: [level: B]

Encoder pulse is not detected by the DJF/RDH main board in the main motor on condition. The first time, a jam occurs. The second time, an SC is displayed.

Possible causes:

• DJF/RDH feed motor defective

• DJF/RDH transport motor defective

• DJF/RDH feed out motor defective

• DJF/RDH inverter motor defective

1.15 FINISHER/SORTER STAPLER

SC 730 - Abnormal *transport motor sorter stapler/finisher) movement

Definition: [level: D]

When the encoder pulse is not detected by the SS (or finisher) main board for 200 ms after the *transport motor starts, a jam is displayed. If this occurs twice, an SC is displayed.

Possible causes:

• *Transport motor

Sorter Stapler Finisher

* Main motor Transport drive motor

SC 731 - Abnormal bin drive (lift) motor movement (sorter staplers)

Definition: [level: B]

If the wheel sensor (bin lift timing sensors) is not off after 2 seconds from when the bin drive (lift) motor stars, jam "R2" is indicated. If the wheel sensor (bin lift timing sensors) is not on after 2 seconds from when the wheel sensor (bin lift timing sensors) detects off, jam "R2" is indicated.

If the condition above occurs twice, an SC is displayed.

Possible causes:

• Wheel sensor (bin lift timing sensors) defective

• Bin drive (Lift) motor defective

SC 732 - Tray shift motor (finisher)

Definition: [level: B]

The shift tray half turn sensor does not detect the on condition for 2 seconds after the finisher tray shift motor starts. The first time, a jam is indicated. The 2nd time, an SC is displayed.

Possible causes:

• Tray shift motor defective

• Shift tray half turn sensor defective

SC 733 - Shift tray lift motor (finisher)

Definition: [level: B]

The stack height sensor 1 or 2 do not detect the on condition for the specified time after the finisher shift tray lift motor.

Possible causes:

• Shift tray lift motor defective

• Stack height sensor 1 or 2 defective

SC 735 - Abnormal jogger motor movement (sorter staplers/finisher)

Definition: [level: B]

When the jogger moves back to the home position, the jogger home position sensor does not detect the on condition within 650 pulses. Then, a jam is indicated. When the jogger moves from the home position forward, and moves back to the home position, the jogger home position sensor does not detect the on condition within 100 pulses. Then, a jam is indicated.

If the above condition occurs twice, an SC is displayed.

Possible causes:

• Jogger motor defective

• Jogger home position sensor defective

SC 737 - Abnormal gripper motor movement (sorter staplers)

Definition: [level: B]

When the gripper moves to the staple position, the gripper home position sensor does not detect the on condition. Then a jam is indicated. When the gripper moves from the staple position to the bin position, the gripper home position sensor does not detect the on condition within 1070 pulses. Then a jam is indicated. When the gripper moves to the home position, the gripper home position sensor does not detect the on condition within 1.25 seconds. Then a jam

is indicated. When the gripper moves from the home position forward, and moves back to the home position, the gripper home position does not detect the on condition within 500 ms or more. Then a jam is indicated. If the above condition occurs twice, an SC is displayed.

Possible causes:

• Gripper motor defective

• Gripper home position sensor defective

SC 738 - Abnormal staple motor movement (sorter staplers)

Definition: [level: B]

The staple home position sensor does not detect the on condition within 600 ms after the motor starts. Then a jam is indicated. If this occurs twice, this SC is displayed.

Possible causes:

• Staple unit (staple motor) defective

• Staple is jammed in the staple unit.

SC 740 - Abnormal staple unit drive motor movement (sorter stapler/finisher)

Definition: [level: B]

The staple unit home position sensor does not detect the on condition when the staple unit is in the home position. A jam is indicated. The staple unit home position sensor does not detect the on condition (within 1640 pulses) when the staple unit moves to the home position. A jam is indicated. The staple unit home position sensor does not detect the on condition (within 280 pulses) when the staple unit moves forward from the home position and moves back to the home position. A jam is indicated. If the above condition occurs twice, this SC is displayed.

Possible causes:

• Staple unit drive motor defective

• Staple unit home position sensor defective

SC 741 - Abnormal bin rear plate motor movement (sorter stapler)

Definition: [level: B]

When the rear bin plate is open, the bin rear plate open sensor does not detect the on condition for 750 ms or more after the motor starts. Then a jam is indicated. When the rear bin plate is closed, the bin rear plate home position sensor does not detect the on condition for 750 ms or more after the motor starts. Then a jam is indicated. In the initial condition, the bin rear plate open sensor does not detect the on condition for 1.25 seconds or more after the motor starts. Then a jam is indicated. If the above condition occurs twice, this SC is displayed.

Possible causes:

• Bin rear plate drive motor defective

• Bin rear plate open sensor defective

• Bin rear plate home position sensor defective

SC 742 - Abnormal stack feed out motor movement (finisher)

Definition: [level: B]

No encoder pulses is detected for 500 ms. or more.

Possible causes:

• Stack feed out motor defective

SC 743 - Punch motor abnormal (sorter stapler with punch)

Definition: [level: B]

When turning on the main switch, the punch home position sensor is not activated within 1100 pulses. Then an R2 jam is indicated. In punch mode, the punch home position sensor is not activated within 950 pulses after rotating the punch motor. Then an R2 jam is indicated. If

the above condition occurs twice, this SC is displayed.

Possible causes:

• Punch motor

• Punch home position sensor

SC 744 - Staple jam release abnormal (sorter stapler)

Definition: [level B]

In the initial condition the paper sensor is activated and the staple home position sensor is de-activated. Then, an R3 (staple) jam is indicated. If this condition occurs 4 times in a row, this SC is displayed.

Possible causes:

• Stapler

1.16 OTHERS

SC 900 - Total counter failure (staying in the off condition)

Definition: [level: D]

The total counter stays in the off condition.

Possible causes:

• Total counter defective

SC 901 - Total counter failure (staying in the on condition)

Definition: [level: D]

The total counter stays in the on condition.

Possible causes:

• Total counter defective SC full used toner bottle

Definition: [level: A]

The toner overflow switch is activated.

Possible causes:

• Toner collection bottle is full

• Toner overflow switch defective

NOTE: Clear the SC full used toner bottle as follows:

1) While the main switch is on, open the front doors then take out

the toner collection bottle (used toner bottle).

2) Remove the toner collection bottle then empty and clean the

bottle.

3) Install the empty toner collection bottle.

4) Close the front doors.

SC 940 - Main Switch Abnormal (U.S.A. version only)

Definition: [level: A]

The Main switch does not turn off after sending the reset signal two times in a row.

Possible causes:

• Main switch

• Main PCB

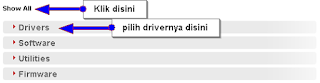

Download :

ERROR SC CODE RICOH

Source Url: http://ricohservice.blogspot.com/